Wisconsin Aluminum Foundry: How Local Foundries Maintain Superior Quality

Wiki Article

Discover the Convenience of Aluminum Castings: Necessary Truths and Providers You Need To Know

Aluminum spreadings are significantly recognized for their versatility across various fields. Their light-weight nature, deterioration resistance, and strength-to-weight proportion make them a recommended option in numerous applications. From vehicle to aerospace, the versatility of these castings is impressive. Yet, the techniques of manufacturing and the range of solutions offered frequently go undetected. Comprehending these facets can significantly affect job outcomes and performance. What essential realities and services should one consider when exploring light weight aluminum spreadings?The Characteristic That Make Light Weight Aluminum Castings Perfect for Numerous Industries

Aluminum spreadings have a special combination of homes that make them incredibly suitable for a wide variety of markets. Their light-weight nature is one of the most significant advantages, permitting for easier handling and minimized transportation prices (Aluminum Castings). Aluminum castings also exhibit outstanding deterioration resistance, which extends the life-span of elements in challenging settings. On top of that, they offer excellent thermal and electrical conductivity, making them perfect for applications calling for efficient heat dissipation or electrical links

Common Applications of Aluminum Castings

Additionally, the electric industry often employs aluminum castings for housings and enclosures, assisting in reliable warmth dissipation and boosting safety. The customer goods industry uses light weight aluminum castings in items such as kitchenware and furnishings, where visual appeals and capability are paramount.

Furthermore, the marine sector relies on aluminum castings for components that withstand rough atmospheres, such as watercraft hulls and fittings. Generally, aluminum castings serve a plethora of functions, showcasing their flexibility and vital duty in modern-day manufacturing processes.

Various Casting Methods Described

Recognizing the numerous casting techniques is essential for selecting the proper method for light weight aluminum castings. 2 popular techniques, sand spreading and die spreading, offer unique benefits and applications. Each technique's unique features influence the last product's quality and viability for certain usages.Sand Spreading Process

While various casting methods exist, sand spreading continues to be among one of the most widely utilized techniques due to its flexibility and cost-effectiveness. This process includes producing a mold and mildew from a combination of sand and a binding representative, which forms the tooth cavity right into which molten light weight aluminum is poured. The sand mold and mildew can be easily formed and reused, permitting the production of intricate geometries. When the aluminum strengthens, the mold and mildew is damaged away, revealing the cast component. Sand casting is particularly ideal for reduced to tool production volumes, making it excellent for custom components. Its adaptability to different sizes and forms, combined with the ability to fit complex styles, better boosts its appeal in different industries.Die Spreading Techniques

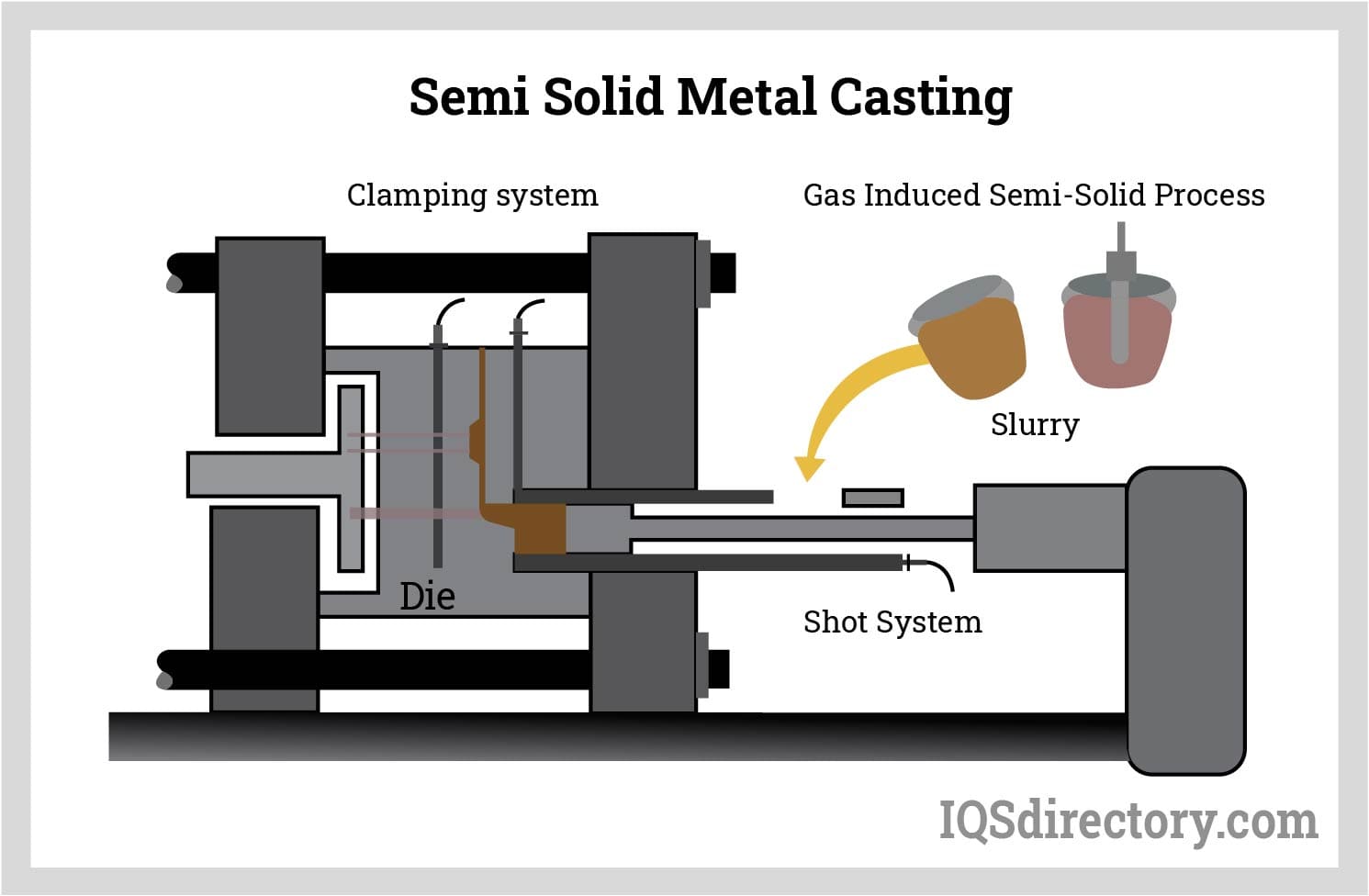

Die casting stands for an unique strategy in the field of light weight aluminum casting techniques, offering high precision and efficiency for automation. This method entails requiring molten light weight aluminum right into a mold and mildew under high stress, making sure a top notch finish and limited tolerances. There are 2 key kinds of die spreading: hot chamber and cool chamber. Hot chamber pass away spreading is ideal for low melting factor alloys and enables rapid manufacturing cycles. On the other hand, cool chamber die casting is used for products with greater melting points, requiring the light weight aluminum to be ladled right into the chamber. Both techniques enable the manufacturing of elaborate designs and intricate shapes, making pass away casting a preferred selection for sectors such as vehicle, aerospace, and customer items.Advantages of Utilizing Light Weight Aluminum Castings

Numerous benefits make light weight aluminum spreadings a preferred choice throughout different industries. To start with, aluminum's lightweight nature substantially lowers the general weight of items, improving their efficiency and efficiency. Furthermore, aluminum spreadings show outstanding rust resistance, which lengthens item life-span and minimizes upkeep costs. The product's high thermal and electrical conductivity also makes it ideal for applications in vehicle and electronics markets.Additionally, light weight aluminum spreadings can be created with intricate styles, permitting producers to develop complicated shapes that meet specific needs. This convenience not only sustains innovative styles however likewise lowers the requirement for added machining processes, saving time and sources. Also, light weight aluminum's recyclability lines up with sustainability objectives, attracting eco aware companies. Jointly, these advantages placement aluminum spreadings as an exceptional option for a variety of applications, guaranteeing sturdiness, performance, and cost-effectiveness in today's open market.

Solutions Offered by Aluminum Casting Manufacturers

In addition, they typically give different casting techniques, such as sand spreading, die casting, and financial investment casting, each suited for various job demands. Quality assurance is another vital service, with manufacturers applying extensive testing and inspection Read Full Report protocols to ensure that castings fulfill industry criteria.

Additionally, aluminum spreading business frequently aid with finishing solutions, consisting of machining, surface treatment, and coating, boosting the final item's longevity and visual appeal. They may supply logistical assistance, assuring timely distribution and effective supply chain management to fulfill customer target dates.

Tips for Selecting the Right Aluminum Casting Partner

Choosing the appropriate aluminum casting companion can substantially impact the success of a job (Metal Castings). To assure compatibility, companies need to first assess the partner's market experience and technological knowledge. A provider with a strong history in details applications can supply important insights and ingenious servicesNext off, her latest blog it is necessary to assess the quality assurance procedures in area. A dependable partner will comply with rigid top quality criteria and provide qualifications where relevant. In addition, reviewing past projects and client testimonials can offer a clearer understanding of the partner's capabilities and reliability.

Cost-effectiveness is also important; however, it must not jeopardize high quality. Companies should look for a balance between price and the level of solution supplied. Open interaction and responsiveness are vital qualities. A companion that prioritizes cooperation cultivates an efficient working partnership, ultimately bring about effective task end results.

Regularly Asked Inquiries

Can Aluminum Castings Be Repaired if Damaged?

Yes, light weight aluminum castings can be repaired if damaged. Wisconsin Aluminum Foundry. Techniques such as welding, brazing, or glue bonding are frequently employed, relying on the degree of the damages and the specific demands of the fixing procedureHow Do Aluminum Castings Compare to Various Other Metals?

Light weight aluminum spreadings are lighter, corrosion-resistant, and much more flexible compared to various other metals like steel or iron. Their exceptional thermal conductivity and recyclability make them a preferred option in numerous industries, enhancing flexibility and performance.What Is the Life-span of Aluminum Castings?

The life-span of aluminum castings commonly ranges from 10 to half a century, depending on ecological problems, alloy make-up, and application. Proper upkeep and safety steps can substantially enhance their durability and durability in various settings.Are Light Weight Aluminum Castings Recyclable?

Yes, light weight aluminum spreadings are recyclable. They can be thawed down and repurposed without losing their integral residential properties, making them an eco friendly choice. This recycling process contributes to sustainability and lowers the demand for brand-new light weight aluminum production.How Do I Preserve Light Weight Aluminum Castings?

To maintain aluminum castings, one must consistently clean them to get rid of dirt and oxidation, apply safety finishings to avoid rust, and inspect for damages to assure durability and structural stability in different applications.The versatility of light weight aluminum castings enables their prevalent use throughout numerous sectors. Comprehending the different casting techniques is necessary for picking the ideal technique for aluminum spreadings. Pass away spreading stands for a distinct approach in the area useful site of light weight aluminum spreading methods, using high accuracy and effectiveness for mass production. Various advantages make aluminum castings a recommended selection across various industries. In addition, they generally offer various casting techniques, such as sand spreading, pass away casting, and financial investment casting, each matched for different project needs.

Report this wiki page